- Author

- A.N. Other and NHSA Webmaster

- Subjects

- Naval technology, Naval history, History - post WWII, Occasional papers, Infrastructure and Facilities

- Tags

-

- RAN Ships

- HMAS Shropshire, HMAS Australia II

- Publication

- June 1982 edition of the Naval Historical Review (all rights reserved)

June 1982 edition of the Naval Historical Review (all rights reserved)

When the Second World War broke out the RAN possessed two 10,000 ton County class cruisers armed with BL 8 inch Mark VIII guns, the barrels of which would need to be relined after 550 equivalent full charges. In times of peace this did not matter a great deal, spare guns were held in store, and barrel changes could be done at the Garden Island Dockyard. But in wartime this state of affairs was unacceptable. The barrels could be changed without much trouble, but the worn barrels would have to be shipped to the United Kingdom for relining, consequently the time involved could not be tolerated. About the only way out of this predicament was to reline the guns in Australia. Problems arose, the main one being that the job had never been carried out in Australia, nor did the machinery and technical know-how exist. It was quite a large job, requiring the old rifled tube to be machined out of the barrel, a new one prepared and then inserted in the barrel. Most of the barrels were fully wire wound, which did not help the matter.

Even if the barrels were relined, the task of testing the guns had to be taken into account. A relined gun has to be given full proof firing to test the piece before it can be issued for service. A proof range existed at Port Wakefield in South Australia, but alas there was no mounting capable of taking an eight-inch barrel.

The relining programme was given the go-ahead, and a section was set up at the Bendigo Ordnance Factory to carry out all the steps required, up to final proof firing. In the 1940s the United Kingdom had its hands full with keeping the British Forces supplied with warlike stores, and could not give much help to Australia. But the United States Navy’s Bureau of Ordnance was able to help, and did. It was quite a lengthy process to reline a gun barrel of this calibre, a gun that was 34 feet long weighing 16 tons 17 cwts. Removing the old liner was accomplished by hydraulically forcing it out in the case of a barrel that had not previously been given a new liner, but in the case of a relined gun the rifling was turned out to accept a new tapered tube. That Bendigo did a good job in this respect is history, there was nothing wrong with an Australian relined 8-inch gun.

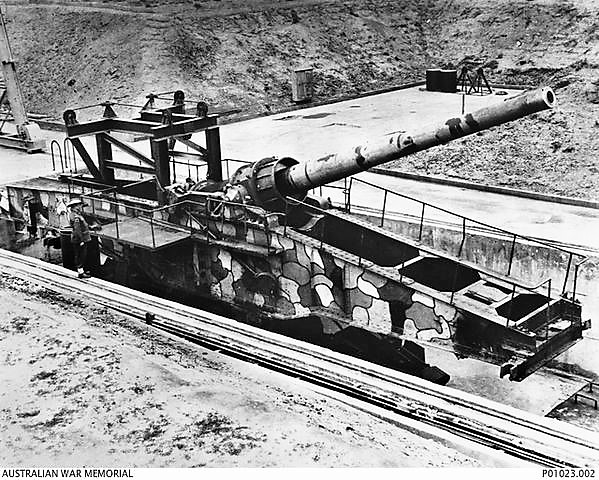

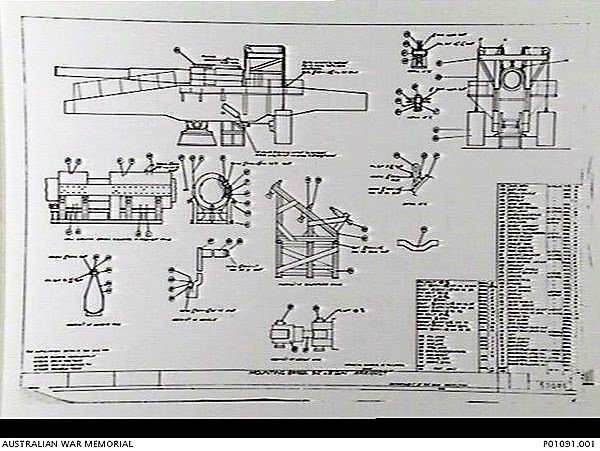

When it came to the actual proof firing the problem existed in obtaining a suitable carriage. Obviously a 9.2” mounting would be ideal, but there were no spares to be had, but at the Canberra Railway Station was a 28cm German Railway gun that had been captured by the AIF near Amiens in 1918. This gun was in fact an 11-inch gun, but the carriage could be adapted to take either the 8-inch or 9.2-inch barrels without much trouble.

The Amiens gun was stripped of its barrel and the carriage was sent down to Port Wakefield and emplaced. Parts of the railway carriage were stored in army depots, with the idea being that after the mount was not required by the proof range, the whole gun could be reassembled and sent back to Canberra. A good thought, but one which unfortunately never took place.

A lot of fast work was carried out to get the relined barrels proved, the mounting did not arrive in Port Wakefield until November 1943, but in January 1944 the first relined barrel was given its proof firing.

Considering the actual work involved in setting up the permanent emplacement, plus the task of getting the mounting from Canberra to the range, this is a commendable effort indeed.

Before the last relined gun was proved in September 1946, no less than eighteen barrels had been relined, and only one failed proof firing. In this case it was not the lining that was the trouble, but the obturator in the breech mechanism, and a subsequent proof firing was carried out with the gun being accepted for service.

One may ask, was the programme worthwhile, as eight years after the last relined barrel was proved, the last 8-inch gun in the British Navy was fired for the last time in HMAS Australia. But we must remember that this was a wartime project, and very much needed. As an illustration, HMAS Shropshire fired some 2,396 rounds of 8 inch between December 1943 and October 1944 and in this case, we can see that her guns would have been at least half worn out at this stage. The programme was necessary and was carried out with great skill, a credit to all concerned.

Today there are a few reminders of this wartime project. The proof range holds some exhibits of shell and charges, and a more important item in one 8-inch barrel. That this barrel exists is pure luck. When the project came to a halt there was an 8-inch barrel that had been used to test ammunition left at the range. This gun had been originally installed as the left gun in B turret in HMS Devonshire in June 1928, but had been relined at Woolwich in 1941, and eventually found itself as the left gun in X turret in Australia. The gun, register number S105L, arrived at Port Wakefield in April 1944. After it was withdrawn from service it became redundant to station requirements and was buried at the range. Years later it was sold as scrap to a metal buyer. Here fate stepped in, as Captain Frank Adlam, MBE, arrived in time to stop the men from cutting up the gun, in fact the workman had the oxy cutter lit up and ready to start when Captain Adlam arrived on the scene. By some high-pressure salesmanship, the worthy Captain persuaded the scrap dealer to refrain from cutting up the gun, and then talked him into presenting it back to the range. It still stands as a monument to the relining programme. Two other barrels existed at Bendigo, register numbers S55L and S61L, and one of these was recently moved to the gun collection at the Australian War Memorial at Canberra.

As for the German railway mounting that was used for test firings, as stated above, it was never re-assembled as one unit. In what can be classed as a classical miscarriage of justice, the mounting was cut up and sold as scrap metal at Port Wakefield, and the load sent off to Japan.