After World War 2 the Daring Class destroyer was designed taking into account the lessons learnt for the ships damaged during the war. Many destroyers had been rendered unpowered because the power plant was centred in one compartment and that had been damaged. These ships were either towed or sunk by friendly ships if towing was impractical.

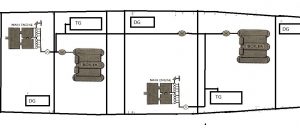

Cruisers and larger ships had the power plants distributed throughout the hull and could absorb more damage. When the Darings were designed, the displacement of destroyers was increased to 3500 Tons and the unit system was employed to give the ship greater resilience to damage. A simplified diagram shows the Diesel and Turbo Generators are distributed throughout the ship and the two boilers are in independent compartments and are able to be cross-connected so that one unit can be supplied by the other.

This was true of the Charles F Adams class as well and hence throughout the 1960s to 1980 Australian Destroyer’s machinery plants were robust and could absorb major damage.

Figure 1 – Daring Class Unit System

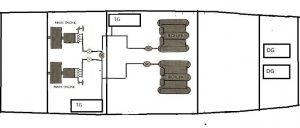

Smaller ships like the Type 12 ASW Frigates had a single pair of machinery rooms, if either room had been damaged the propulsion plant was immediately compromised. Diesel Generators were separated by a major compartment. While the class was expected to be a one hit ship, in war luck can be on your side and HMS Argonaut received two unexploded 1000 lb bombs and was able to be patched up and sailed home to UK.

Figure 2 – DE Type 12 Leander Frigate Figure 2 – DE Type 12 Leander Frigate |

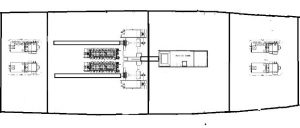

Figure 3 – ANZAC Frigate Figure 3 – ANZAC Frigate |

The ANZAC class has a versatile plant where each engine can drive both shafts. There are three modes

- Each diesel driving its own shaft – manoeuvring mode

- One diesel driving both shafts – cruising mode

- Gas Turbine driving both shafts – Full power mode

This is versatile in peacetime and the distributed power plants will aid in retaining power if the ship is damaged but the engine rooms are a weak point and while the ship is 3600T, the design is much better for crew accommodation than the Daring.

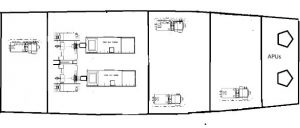

The FFG, which although it displaced 4000T, only had one engine room and one shaft and hence was a large hull but had the same vulnerabilities as the smaller ANZAC class. They did have a distributed power generation system and two auxiliary motors used primarily to manoeuvre the ship alongside but could move the ship at about 3 knots in emergency.

Figure 4 – FFG |

This design has proved robust in absorbing damage but not in maintaining an ability to move except with assistance from other ships.

The new Aegis Hobart class is a large destroyer and both the power requirement and the size has allowed the unit system to be reintroduced into the RAN. The ship’s ability to absorb damage and maintain most of its platform services is enhanced by a sophisicated power system and computer aided damage control.

However, the heart is the two separated and independent units consisting of two diesel generators, a gas turbine and a cruising diesel engine in each unit. The separation of generator plants in particular gives the RAN a platform capability to absorb damage not seen since the cruisers of World War 2.

Figure 5- Hobart Class Unit System

RAN Sewage Plants – 1970 – 2010.

The RAN up to the late 1970s had very simple sewage and waste treatment in its ships. Basically it was flushed into the sea or indeed, into the harbour. In some ports, notably HMAS STIRLING, that meant that crews needed to use facilities ashore.

The last ships built with no facility for sewage other than discharge overboard were the Destroyer Escorts HMAS TORRENS and HMAS SWAN.

The FFG class and the Fremantle Class Patrol Boats had basic storage and rudimentary treatment which allowed the ships to operate in confined waters in line with the current rules and discharge the waste at sea or pump ashore to treatment facilities when in harbour. The ANZAC class, the Armidale Patrol Boats and the current fleet now must control the waste production on board and either treat it or store it until the ship has returned to port.

Perhaps the biggest challenge in our current fleet is the Landing Helicopter Dock ship or the Canberra Class which must treat or store the waste produced by the crew and embarked forces which numbers 1400 people. It must do this in confined waters as well as open sea.

The waste management systems include:

- Incinerators to burn solid wastes,

- Compactors for non-burnable,

- Chilled waste stores, and

- Sewage treatment for waste water.

In confined waters the sewage system treats the waste from both toilets (known as black water) and grey water which comes from showers, washing and galleys. In open water with the ship operating at greater than 4 knots, the waste is pumped overboard.

The sewage system in the Canberra Class is similar to those units found in cruise liners and relies on developing an environment in the system that effectively breaks down the waste into burnable solid waste and neutral water which can be discharged over the side.

Figure 1- Schematic of the sewage system

The waste is collected in a vacuum tank (collector) which separates the waste where it is treated through a refining system where waste is broken down biologically and the filtered water discharged into the sea. The biological treatment process uses all the incoming sewage as food for microorganisms. The raw sewage consumed by the microorganisms is used to provide energy for cell activity and material for cell reproduction.

This plant uses aerobic bacteria (air required) to treat the sewage. This bacteria requires oxygen for their breathing and synthesis process. They consume the organic waste material in sewage and release carbon dioxide and water vapour as by-products. Solids generated are dried by centrifuge and then fed to incineration thereby reducing waste to almost nothing.

In emergency the tanks will hold a full day’s discharge with a full complement on-board but this would require the ship to proceed to open sea to discharge.

Figure 2 – Sewage Treatment Plant